Automatic dishcloth cutting machine

| Dongguan City South Necon machinery Co.,Ltd was an enterprise with professinal R&D and manfatured industrial ultrasonic equipment.The company is trying to provide automatic mechanical equipment for the Chinese machinery industry, providing diversifi Product name:Automatic dishcloth cutting machine Product model:NK-XWB1542 Production unit:Dongguan City South Nekon Machinery CO.,LTD Upload time:2018/12/24 15:38:31 clicks : |

Model No:NK-XWB1542

Size:3000*900*1900mm

Voltage:220V

Capacity:15-30pcs/min

Power:4200W

Air Pressure:4-6kg/cm2

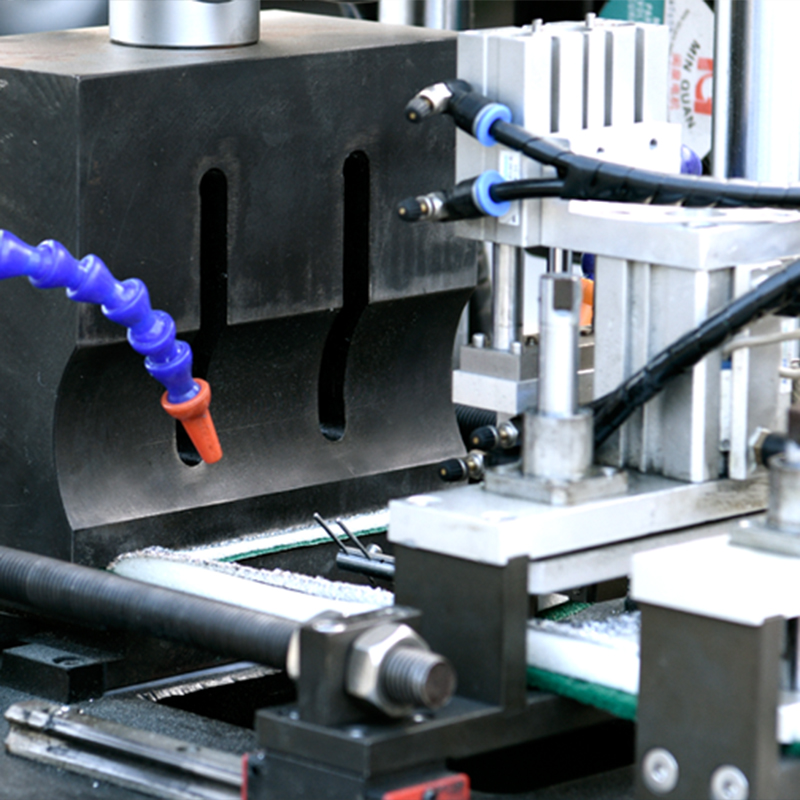

The full-automatic washing cloth punching and cutting machine uses NTK transducer and uses non-woven fabric, meltblown cloth and other raw materials to produce filter cotton of various shapes and sizes by using the pressing and cutting function of ultrasonic waves, which can be completed at one time from multiple processes such as feeding, trimming, welding and the like, and can save 2 - 4 labor compared with the traditional process.

Product features:

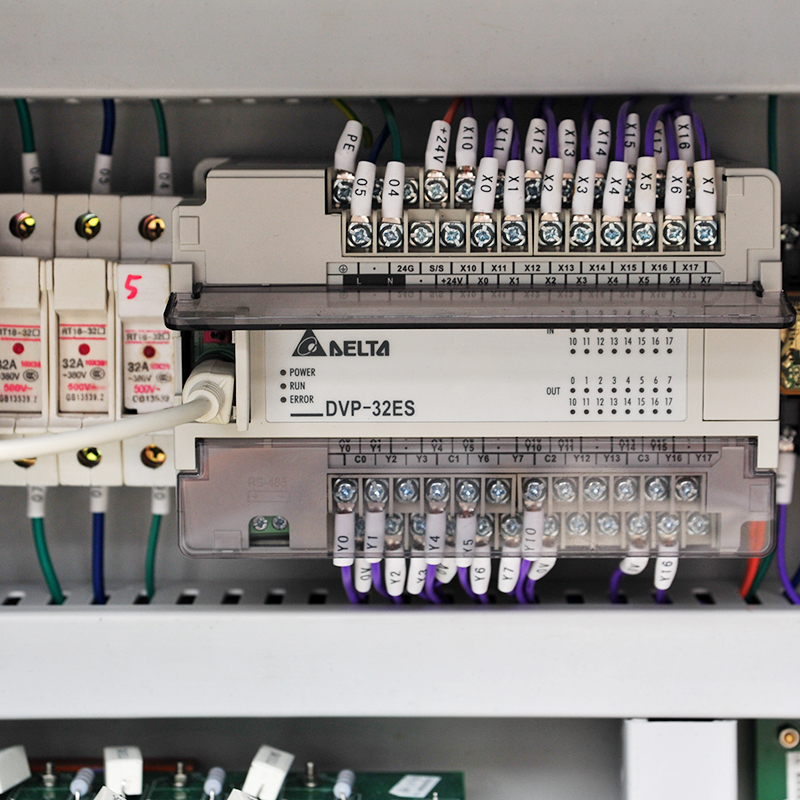

1. The operation panel is clear, PLC program control, easy to operate, easy to learn and understand; 2. Using NTK transducer, the output is strong, stable and durable;

3. The ultrasonic steel mould is imported from Taiwan with beautiful appearance, high hardness and no easy abrasion.

4. The feeding system adopts cylinder belt material, with accurate feeding, small error and no material deformation.

Product features:

1. Design a multi-layer feeding rack to ensure smooth and tidy feeding;

2. Pulling the barrel into the material, positioning is more accurate, the width of raw materials can be controlled to a minimum, and the cost can be saved;

3. The length and size of the finished product are controlled uniformly with a deviation of plus or MINUS 1 mm, which can effectively control the length of the finished product, so that the slicing can not only meet the requirements of production technology, but also eliminate waste.

4, independent material rack, convenient to take and place and adjust raw materials;

5. The degree of automation of equipment is high, and the requirements for operators are low, so that raw materials can be taken and put and finished products can be finished.

6. Automatic counting can effectively control production efficiency and production progress. 7. The rotary control box can adjust the direction of the control box according to the customer's requirements.

8. Automatic molding, discharging and collecting of waste materials, so as to achieve automatic exit of waste materials and reduce the number of employees;

9. The whole feeding rack adopts an all-aluminum alloy rack, which has a light and beautiful appearance and does not rust, making people shine at the moment.

10. This machine adopts ultrasonic Taiwan system, Japanese transducer, stable performance and convenient operation. 11. The automatic ultrasonic welding wheel is made of imported high-quality steel DC53, thus prolonging the service life of the mold and making it wear-resistant and durable.

12. The ultrasonic die is made of Cr12MoV material, which has better hardness than common die materials, is suitable for long-time wave generation and is not easy to crack and deform.

The above parameters and configuration is for reference only, specific configuration by mutual agreement shall prevail

Size:3000*900*1900mm

Voltage:220V

Capacity:15-30pcs/min

Power:4200W

Air Pressure:4-6kg/cm2

The full-automatic washing cloth punching and cutting machine uses NTK transducer and uses non-woven fabric, meltblown cloth and other raw materials to produce filter cotton of various shapes and sizes by using the pressing and cutting function of ultrasonic waves, which can be completed at one time from multiple processes such as feeding, trimming, welding and the like, and can save 2 - 4 labor compared with the traditional process.

Product features:

1. The operation panel is clear, PLC program control, easy to operate, easy to learn and understand; 2. Using NTK transducer, the output is strong, stable and durable;

3. The ultrasonic steel mould is imported from Taiwan with beautiful appearance, high hardness and no easy abrasion.

4. The feeding system adopts cylinder belt material, with accurate feeding, small error and no material deformation.

Product features:

1. Design a multi-layer feeding rack to ensure smooth and tidy feeding;

2. Pulling the barrel into the material, positioning is more accurate, the width of raw materials can be controlled to a minimum, and the cost can be saved;

3. The length and size of the finished product are controlled uniformly with a deviation of plus or MINUS 1 mm, which can effectively control the length of the finished product, so that the slicing can not only meet the requirements of production technology, but also eliminate waste.

4, independent material rack, convenient to take and place and adjust raw materials;

5. The degree of automation of equipment is high, and the requirements for operators are low, so that raw materials can be taken and put and finished products can be finished.

6. Automatic counting can effectively control production efficiency and production progress. 7. The rotary control box can adjust the direction of the control box according to the customer's requirements.

8. Automatic molding, discharging and collecting of waste materials, so as to achieve automatic exit of waste materials and reduce the number of employees;

9. The whole feeding rack adopts an all-aluminum alloy rack, which has a light and beautiful appearance and does not rust, making people shine at the moment.

10. This machine adopts ultrasonic Taiwan system, Japanese transducer, stable performance and convenient operation. 11. The automatic ultrasonic welding wheel is made of imported high-quality steel DC53, thus prolonging the service life of the mold and making it wear-resistant and durable.

12. The ultrasonic die is made of Cr12MoV material, which has better hardness than common die materials, is suitable for long-time wave generation and is not easy to crack and deform.

The above parameters and configuration is for reference only, specific configuration by mutual agreement shall prevail